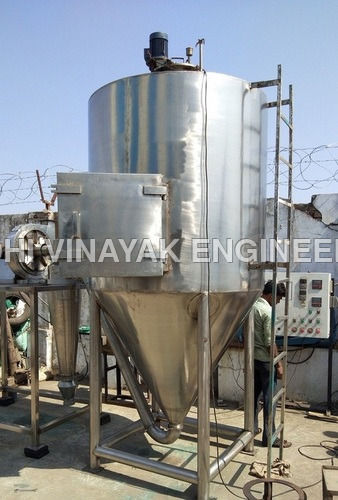

Pilot Spray Dryer

650000.00 INR/Unit

Product Details:

- Power 5 - 25 kW

- Heat Source Electrical / Steam / Oil Fired

- Power Consumption Depends on model and capacity

- Temperature 150-200C

- Fuel Type Electricity / Oil

- Material Stainless Steel

- Voltage 220-440 V

- Click to view more

X

Pilot Spray Dryer Price And Quantity

- 1 , , Unit

- 550000.00 - 1500000.00 INR/Unit

- 650000.00 INR/Unit

Pilot Spray Dryer Product Specifications

- Electrical / Steam / Oil Fired

- Spray Drying

- 5 - 25 kW

- Customizable

- Electricity / Oil

- 150-200C

- Stainless Steel

- Depends on model and capacity

- 220-440 V

Pilot Spray Dryer Trade Information

- Ahmedabad

- 10 , , Unit Per Month

- 15 Days

- Western Europe, Australia, North America, Eastern Europe, Middle East, South America, Asia, Central America, Africa

- All India

Product Description

Pilot Spray Dryers are manufactured by using latest advanced technology, which gives rise to the excellent functional system. This type of system runs on electricity and widely used for the production of powder on small scale. This skid mounted Pilot Spray Dryer is available in different configurations for various research and development applications in various industrial sectors. Our esteemed customers can avail this durable equipment at leading market prices.

Specification

|

Minimum Order Quantity |

1 Unit |

|

Voltage |

220 Volt, also available in 440 Volt |

Versatile Drying for Multiple Industries

This pilot spray dryer is engineered to serve varied sectors including pharmaceuticals, chemicals, food, and dairy. Its adaptable design accommodates different feed types and product requirements, making it suitable for process development and small production runs. The dryers robust construction and advanced features ensure operational flexibility and reliable product outcomes in industrial and laboratory environments alike.

User-Friendly Operation and Maintenance

Operators will appreciate the intuitive control panels, choice of automatic or semi-automatic modes, and efficient clean-in-place system. The double-walled, insulated chamber maintains temperature stability while mirror or matte finishes provide easy cleaning and aesthetic options. Safety, convenience, and minimal downtime are at the forefront of its design, supporting consistent performance with straightforward maintenance routines.

FAQs of Pilot Spray Dryer:

Q: How does the spray dryer ensure a high product recovery rate?

A: The spray dryer is designed with efficient rotary or nozzle atomizers and a controlled airflow system, achieving product recovery rates of 95% or above. Precision in atomization and optimized drying parameters minimize product loss and ensure maximum yield.Q: What types of feed materials can be processed in this spray dryer?

A: This unit supports a wide range of feed types including slurry, solution, and suspension, allowing flexibility to handle various industrial and laboratory substances across pharmaceutical, chemical, food, and dairy applications.Q: When is clean-in-place (CIP) system utilization recommended?

A: The CIP system is recommended after each batch or product changeover and during regular maintenance schedules. This ensures the interior is thoroughly cleaned, preventing cross-contamination and maintaining hygiene standards required in sensitive industries.Q: Where can this spray dryer be installed within a facility?

A: The dryer can be skid mounted for mobility or floor mounted for fixed installation, catering to different spatial requirements and operational preferences within industrial or pilot plant settings.Q: What are the benefits of adjustable air flow and double-walled chamber construction?

A: Adjustable air flow enhances process control, accommodating diverse drying needs, while the double-walled, insulated chamber ensures thermal efficiency, consistent product quality, and operator safety by reducing heat loss.Q: How does the exhaust system contribute to efficient operation?

A: The exhaust system, available with either a cyclone separator or bag filter, effectively manages separated particulates and clean air discharge. This supports compliance with environmental standards and maintains a clean operational area.Q: Why is noise level control important in this spray dryer?

A: Maintaining noise levels below 75 dB ensures a comfortable work environment, reduces fatigue for operators, and complies with workplace safety standards, enhancing overall productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email