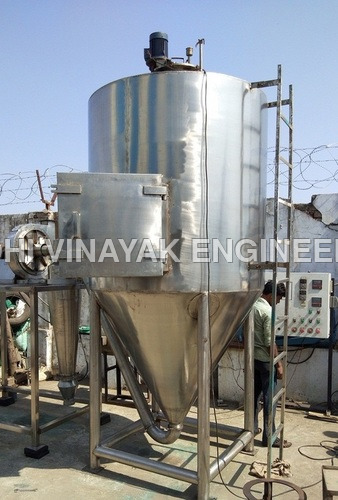

Pilot Spin Flash Dryer

Product Details:

- Fuel Type Electricity / Oil / Gas

- Power Consumption . 5-7 Kilowatt (kW)

- Temperature Up to 250 Celsius (oC)

- Heat Source Steam / Thermic Fluid / Electric

- Power 7.5 Horsepower (HP)

- Material Stainless Steel

- Voltage 220-440 Volt (v)

- Click to view more

Pilot Spin Flash Dryer Price And Quantity

- 1 Unit

- 7500000 INR/Unit

- Customized as per requirement

- Matt / Mirror as per order

- Powder drying Pharmaceuticals, Food, Chemicals

- cGMP compliant

- With bag filter

- Continuous duty

- Included for powder separation

- Skid mounted, portable

- 10-50 kg/hr (pilot scale)

- Screw feeder with variable speed

- Digital, PLC-based automation

- Up to 5% final moisture

Pilot Spin Flash Dryer Product Specifications

- Sliver

- 1500 x 1200 x 2000 Millimeter (mm)

- Steam / Thermic Fluid / Electric

- Stainless Steel

- Up to 250 Celsius (oC)

- Electricity / Oil / Gas

- 1 Year

- Spin Flash Drying

- . 5-7 Kilowatt (kW)

- 7.5 Horsepower (HP)

- 220-440 Volt (v)

- Customized as per requirement

- Matt / Mirror as per order

- Powder drying Pharmaceuticals, Food, Chemicals

- cGMP compliant

- With bag filter

- Continuous duty

- Included for powder separation

- Skid mounted, portable

- 10-50 kg/hr (pilot scale)

- Screw feeder with variable speed

- Digital, PLC-based automation

- Up to 5% final moisture

Pilot Spin Flash Dryer Trade Information

- Ahmedabad

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 15 Days

- All India

Product Description

We are devoted to provide high grade Pilot Flash Dryer, which is manufactured by using latest advanced technology to provide excellent performance. It is highly suitable for drying applications like for semi dried powders, filter cakes and so on. The process of drying takes place inside the cylindrical drying chamber, which is the heart of the the drying process. Our valuable clients can order this dryer system in different configurations as per their desired requirements. Along with being an excellent performer, it is also a cost effective solution which is durable in nature.

Technical Specification

|

Power |

5.5 Kw |

|

Usage |

R & D Purpose and for small quantity of Production |

|

Voltage |

220 Volt, also available in 440 Volt |

|

Design |

Standard |

Advanced Spin Flash Drying Technology

Utilizing state-of-the-art Spin Flash Drying, this pilot dryer achieves rapid moisture reduction to produce high-quality powders consistently. The process ensures efficient thermal transfer and uniform drying, essential for sensitive products such as pharmaceuticals and specialized chemicals.

Flexible and User-Friendly Operation

The system features a digital PLC-based control panel, allowing precise automation and monitoring. With a screw feeder offering variable speeds, users can optimize feeding rates according to specific material requirements for enhanced control and consistent results.

Robust Design for Safety and Compliance

Built with premium stainless steel and a choice of matt or mirror finish, the dryer meets cGMP standards. The inclusion of skid mounting enables portable installation, while advanced filters and a cyclone separator guarantee safe exhaust and effective powder separation.

FAQs of Pilot Spin Flash Dryer:

Q: How does the Pilot Spin Flash Dryer achieve moisture reduction up to 5% in powder drying applications?

A: The dryer utilizes rapid thermal transfer via Spin Flash technology, allowing efficient heat distribution across the product. Controlled air flow and variable feed rates ensure consistent drying, reaching moisture levels as low as 5% for powders.Q: What materials and industries can the Pilot Spin Flash Dryer be used for?

A: It is designed for drying powders in pharmaceuticals, food, and chemical industries. The system supports a wide range of feed materials that require controlled moisture content for product quality and stability.Q: When is it recommended to use the Pilot Spin Flash Dryer over traditional dryers?

A: This dryer is ideal for pilot-scale operations that require a compact footprint, precise moisture control, and continuous operation. It is especially suited for small batch R&D, test production, or pre-commercialization phases.Q: Where can the Pilot Spin Flash Dryer be installed and operated?

A: Its skid-mounted, portable design allows for easy installation across different industrial settings, laboratories, or pilot plants. It operates efficiently in various facility configurations, adapting to specific space and workflow needs.Q: What is the process for powder separation and exhaust management in this system?

A: A cyclone separator effectively separates dried powder from the air stream, while an integrated bag filter system ensures safe exhaust of fine particulates, maintaining a clean and compliant work environment.Q: How does the control panel and automation enhance user experience and safety?

A: The digital, PLC-based control panel provides intuitive operation, precise system regulation, and automated safety checks. This minimizes manual intervention and ensures reliable, contamination-free drying processes.Q: What are the key benefits of using the Pilot Spin Flash Dryer for powder production?

A: Key benefits include rapid and uniform drying, low final moisture content, easy setup and mobility, compliance with cGMP standards, and versatility in heat source and fuel types. The system optimizes production efficiency and product quality for demanding industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese